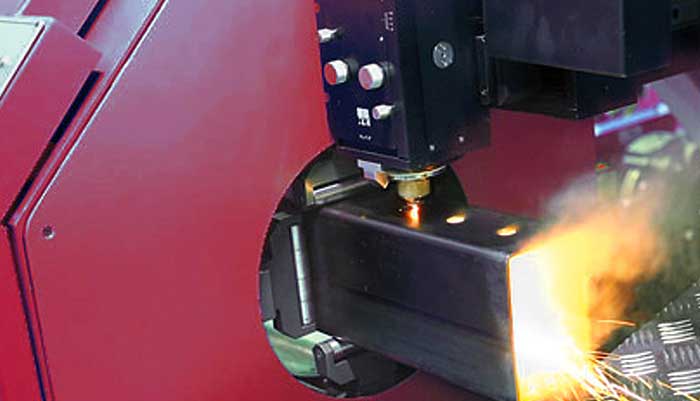

Tube Lasers Cutting Systems

We are leaders in the production of advanced laser-cutting technologies, as well as CNC controls and automated systems.

The applications of tubes and profiles are numerous. The use of processed tubes and profiles is endless, in every industry. The laser-assisted production of tubes and profile offers many possibilities for design and manufacturing.